These Welding Positioners are designed for welding application where welding in circular part is required. They are also very useful for positioning the job for better welding position.

| Model | HB-50 | HB-150 | HB-300 | HB-500 | HB-1000 | HB-2000 | HB-5000 |

|---|---|---|---|---|---|---|---|

| Load Carrying | 50 | 150 | 300 | 500 | 1000 | 2000 | 5000 |

| Capacity at 0deg (Kg) | 25 | 75 | 150 | 250 | 500 | 1000 | 2500 |

| Rotation Speed (RPM) | 0.5-8 | 0.25-1.13 | 0.19-0.78 | 0.15-0.75 | 0.1-0.42 | 0.08-0.33 | 0.05-0.5 |

| Drive Method | AC motor with reduction gear and VFD | AC motor with reduction gear and VFD | AC motor with reduction gear and VFD | AC motor with reduction gear and VFD | AC gear motor with VFD | AC motor with reduction gear and VFD | |

| Face Plate Diameter (mm) | 305 | 450 | 650 | 800 | 1200 | 1500 | 1500 |

| Tilting Method | Manual | Motorized | Motorized | Motorized | Motorized | ||

| Tilting Angle | 0 to 90 | 0 to 90 | 0 to 90 | 0 to 135 | 0 to 135 | 0 to 135 | 0 to 135 |

| Center of gravity (mm) | 100 | 100 | 150 | 150 | 150 | 150 | 150 |

Warpp make welding manipulators are designed and manufactured to be used in welding automation where long seam welding needs to be done and also used as a weld head locator in case of circular seam welding. Precision machined column and boom ensures smooth travel of boom, which makes it suitable for GTAW,GMAW and SAW applications. These manipulators are available in fixed column, 360deg manual/motorized rotation and manual/motorized trolleys.

| Model | 2*2 | 3*3 | 4*4 |

|---|---|---|---|

| Column Height (mm) | 3500 | 4500 | 5400 |

| Boom Length (mm) | 4000 | 5000 | 6000 |

| Effective Vertical Boom travel (mm) | 2000 | 3000 | 4000 |

| Effective Horizontal Boom travel (mm) | 2000 | 3000 | 4000 |

| Lifting Speed of Boom (m/min) | 1 | 1 | 1 |

| Travel Speed of Boom (m/min) | 0.1-1.2 | 0.1-1.2 | 0.1-1.2 |

| Foundation Plate (L*W) | 700*700 | 1000*1000 | 1200*1200 |

| Boom Lifiting Motor (KW) | 0.5 | 0.75 | 1 |

| Boom Travel Motor (KW) | 0.25 | 0.5 | 0.5 |

| Input Supply | 3 Phase, 440 V AC | ||

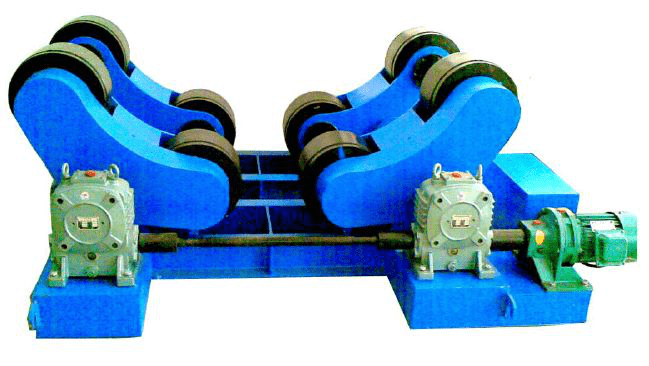

These rotators are designed and manufactured to suit need of rotating shells for circular seam welding. Precisely fabricated and machined structure along with perfectly aligned system ensures smooth rotation of the shells. There is no need to adjust the distance between the turning rolls as they adjust as per the diameter of the shell.

| Model | Load Capacity (Tons) | Wheel Dia (mm) | Work Piece Dia (mm) | Wheel width (mm) |

|---|---|---|---|---|

| ZT- 5 | 5 | 250 | 250~2300 | 100 |

| ZT- 10 | 10 | 300 | 300~2800 | 120 |

| ZT- 20 | 20 | 300 | 500~3800 | 120 |

| ZT- 30 | 30 | 400 | 500-3800 | 150 |

| ZT- 50 | 50 | 400 | 600-4500 | 150 |

| No.of Wheels - 8 | ||||

| Wheel Speed - 125~1000 mm/minute | ||||

| Input Power - 3 Phase 380-440 Volts 50 HZ Supply | ||||

| Wheel Material - Rubber + Cl Steel/Polyuretdane + C.l.Steel | ||||

We are one of the very experienced dealers, with a successfull completion of our 18th year and have been showing an exponential growth in dealing quality products to our clients. We deal and provide our customers the best quality available in the market and consider their satisfaction as our fore most principle of business..